Client

Société Tunisienne des Industries de Raffinage

Location

Zarzouna - Bizerte

Start of work

2011

Delivery date

2011

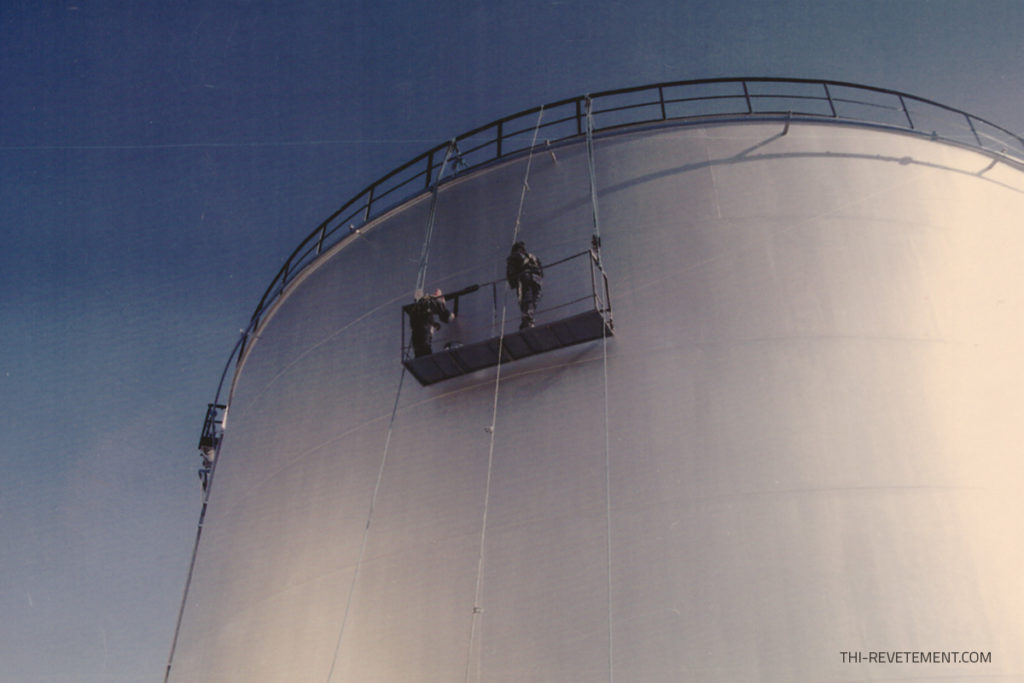

Hydrocarbon storage tanks require periodic protection against corrosion by sandblasting and anti-corrosion paint or special coatings– (Bizerte refinery STIR estimates this at 7 years).

Our intervention consists in renewing the protective coating by sandblasting and painting of the crud oil storage tank S7 while respecting the execution times which must be as short as possible, the safety standards, the markings of the pipes and the guarantee of maintenance of the applied system which must meet the usual chemical, physical and mechanical constraints in the region of Bizerte in northern Tunisia.

The system begins with the sandblasting of the surfaces to apply the new anti-corrosion painting. Sandblasting is done by abrasive projection using compressed air, the degree of sandblasting to be achieved is SA 2.5, the purpose of sandblasting is to expose the steel, the sandblasting operation allows then to remove the rust, the old anti-corrosion painting and any foreign bodies.

As soon as the sandblasting is finished, the first coat of anti-corrosion painting is applied; the primer coat of anti-corrosion painting is used to protect the bare surface after sandblasting.

The painting system is further reinforced with an intermediate layer of anti-corrosion painting. The anti-corrosion painting system is finally closed with a coat of waterproof finishing painting. The complete system of sandblasting and anti-corrosion painting applied is able to resist chemical agents, mechanical stress and sunlight.