1. Sector of Anti Corrosion Coatings and linings services in Libya

1.1 Industries that require anticorrosive coatings in Libya: oil sector

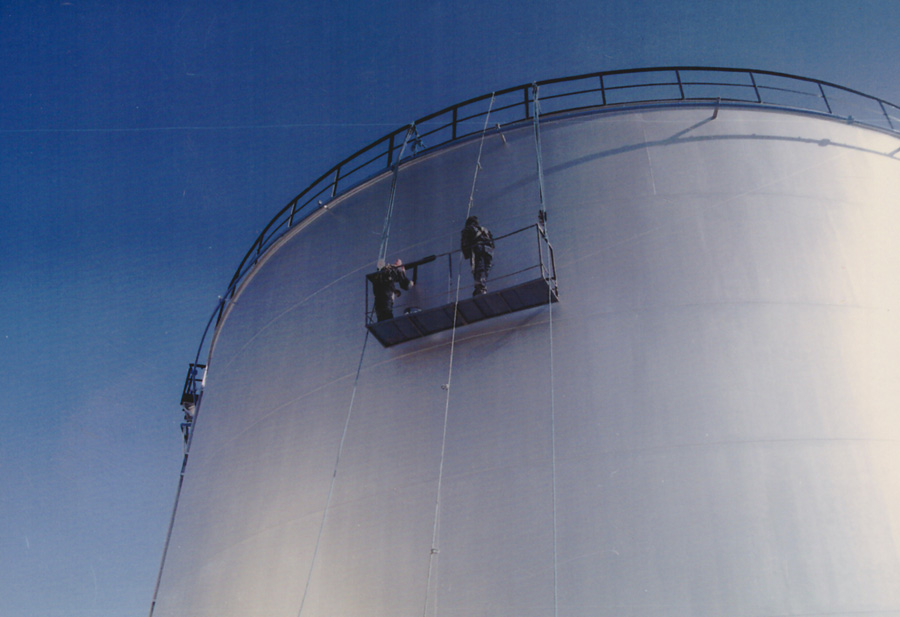

The oil sector in Libya represents the largest market using anticorrosive coatings and linings services.

The fairly large storage capacity is dispersed throughout the ports of Libya, which strains them against the salty humidity released by the sea, which is at the same time contaminated by the industrial products released by the oil processing plants.

The storage tanks of the various petroleum products in Libya require adequate anti-corrosive coatings either on the outside to resist external corrosion or internal coatings to resist the corrosion caused by the products mixed with hydrocarbons.

The refining and processing plants for petroleum products in Libya are also located on the sea edge, which requires them to have very large anti-corrosion coating programs.

1.2. Industries that require anti-corrosion coatings in Libya: electric power sector

In Libya there are several electrical power generation stations, most of which are located at the sea edge and which also represent an important market for anti-corrosion coatings and surface linings services.

Libya also has a network of high voltage transmission lines.

The high voltage transmission lines in Libya are formed by many thousands of kilometers; this network is permanently affected by corrosion and requires an anti-corrosion coating program to protect it.

2. Application of anticorrosive coatings and linings services in Libya:

2.1. Anticorrosive coating for new works in Libya.

New installations intended for the extraction of oil in Libya, for storage or for transport are always equipped with a treatment against corrosion to protect it against corrosion stresses.

Anti-corrosion coatings are always studied for each case according to the environment and the products manufactured by the unit and the location of the region in Libya.

The lifespan of an anti-corrosion coating depends on the corrosion stress it is subjected to and the quality of the coating required by the specifications of the contracting authority in Libya.

The difference between one anti-corrosion coating system and another is generally characterized by the quality of the coating material and its thickness.

2.2. Maintenance Anticorrosive coatings in Libya.

Old industrial installations in Libya require a serious maintenance program by anti-corrosion coating and surface linings services.

Base coating, in Libya, is generally carried out and weakened in a period between three and five years except for the very thick interior coatings which are weakened from ten years.

A maintenance anti-corrosion coating program is essential to protect industrial facilities in Libya and extend their lifespan.

The maintenance anti-corrosion coating is generally similar to the base coating except if it is found over the years that an anti-corrosion coating is insufficient, it is then replaced by a new coating which is more effective. Industrial companies in Libya have specialized design offices that control and study anti-corrosion coating systems in Libya.

2.3. Various anti corrosion coatings and surface protection services

2.3.1 Surface preparation services:

– Sandblasting

– Shot blasting

– Brushing

– Chemical stripper

2-3.2 Anti-Corrosion Coating Services:

– Paintings

– Epoxy resins

-GRP

– Galvanization

– Rubber

Some of our projects;