Recent Advances in Protective Coating of Crude Oil Storage Tanks

| – Conference: The 6th Libyan Corrosion Conference, Tripoli, Libya, – November2007, Pp 460-472. – Authors: Mohamed Abdelgawad Gebril , Farag Shuaeib – Source: researchgate.net – Recent Advances in Protective Coating of Crude Oil Storage Tanks |

ABSTRACT

As coating developments are occurring every year. Therefore, a recent advances

investigation and analysis is necessary at certain milestone intervals. Furthermore, actual

experience feed back about the advantages and/or shortcoming of certain product or

design would be beneficial. The oil and gas particular field and more particularly the

storage tank coating systems are considered in this study. At the beginning, tank

corrosion problems are outlined and then a comprehensive theoretical characterization

and description for the major types of coatings is presented. The selection bases are also

stated for each type of coating. Then a crude oil floating roof storage tank case study has

been undertaken which illustrates the coating selection and discuses the current tank

coating problems. In this case study, coating selection was based on two approaches. The

first is by referring to the approved coating suppliers, and the second is by referring to

current coating specification used by two major oil and gas local companies. Selection

results from the two approaches are then compared and discussed. Research findings are

then concluded.

1. INTRODUCTION

Steel Storage tanks are used to store fluids such as crude oil, intermediate and refined

products, gas, chemicals, waste products, aqueous mixtures, and water. Corrosion is the

prime cause of the deterioration of steel storage tanks and accessories; therefore, control

and prevention of tank corrosion is of prime importance for efficient plant economics and

safety. One of the most efficient methods of tank corrosion prevention is by applying a

suitable coating. Therefore, the aim of this article is to provide up-to-date technological

directions in this field and compare them with what is currently being used by some of

the local companies. However, to begin with it was found worth to provide a brief

overview of tank corrosion problems which is usually encountered in the oil and gas

plants.

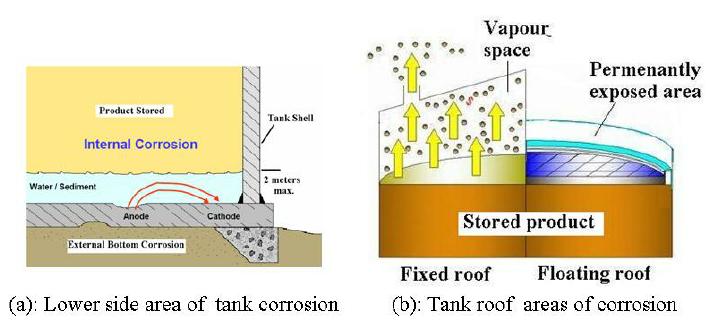

Tank corrosion can either be external or internal. Figure (1)-a, shows the areas of

corrosion for lower side of the tank, while Figure (1)-b, shows the areas of corrosion on

top side according to the tank roof type. External corrosion of tank bottoms can be

significant. The foundation material used for forming a pad under the bottom may contain

materials that are corrosive. For example, cinders may contain sulfur compounds that

become very corrosive when moistened. The presence of clay, wood, gravel, or crushed

stone as a contaminant in a sand pad may cause pitting corrosion at each point of contact.

Faulty pad preparation or poor drainage may allow water to remain in contact with the

tank bottom. If a tank previously leaked corrosive fluid through the bottom, accumulation

of the fluid under the tank can cause external corrosion of the tank bottom. For tanks that

are supported above grade, as shown in Figure 1a, an improperly sealed ringwall may

allow moisture to accumulate between the tank and the support, thereby accelerating

corrosion [1]. External corrosion also occurs when external insulation picks up ground

water, or when damaged or improperly sealed openings around nozzles and attachments

allow water ingress. Atmospheric corrosion can occur on all external parts of a tank. This

type of corrosion may range from negligible to severe, depending on the atmospheric

conditions of the locality. A sulfurous or acidic atmosphere can damage protective

coatings and increase the rate of corrosion. External surfaces of the tank and auxiliary

equipment will corrode more rapidly if they are not protected with paint or other

protective coatings or with cathodic protection where surfaces are in contact with

moisture. Continuous water contact due to pockets or depressions will be likely to cause

localized corrosion. Areas susceptible to this should be coated with coatings designed to

withstand immersion. The type of tank and the construction details used can affect the

location and extent of external corrosion.

The occurrence of internal corrosion of a storage tank depends on the contents of the tank

and the material of which the tank is constructed. In some cases it is necessary to use

linings (coatings) that are more resistant to the corrosive properties of the stored fluid

than are the tank construction materials. In some particularly corrosive services, it may be

necessary to construct the tanks of a corrosion resistant material [1].

Crude oil and petroleum product tanks are usually constructed of carbon steel. Internal

corrosion in the vapor space above the liquid of the fixed roof tanks is commonly caused

by hydrogen sulfide vapor, water vapor, oxygen, or any combination of the three (See

Figure 1-b). In the areas covered by the stored liquid, corrosion is commonly caused by

acid salts, hydrogen sulfide or other sulfur compounds, or contaminated water that settles

out with solids on the bottom of the tank. This bottom layer is typically referred to as

bottom sediment and water (BS&W) as shown in Figure (1)-a. Coating of tank surface,

particularly paints and lacquers, is by far the most important of all methods for corrosion

prevention and probably accounts for about half of all costs spent on anti-corrosion

measures.

2. PROPERTIES OF PAINTS

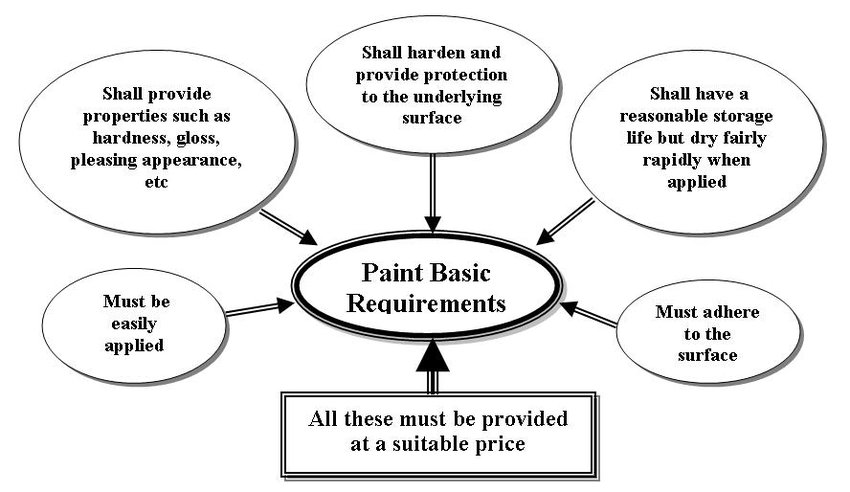

Generally, the most obvious properties that a paint must have are shown by the sketch of

Figure (2):

Often, a single paint will not have all the required properties so a number of coats, or

paint system, will be applied rather than a single coat. The first coat or primer must

protect and adhere to the tank surface (The paint teeth). The paint film is built up by

intermediate coats and a top coat or finishing coat provides protection against sunlight,

abrasion, etc and often provides decoration. Primers and topcoats must, of course, be

compatible with one another, and coating suppliers should be consulted for such

information. Due to application costs being far higher than material costs, the move is to

reduce to a minimum the number of coats in a paint system with a single high-build

system.

Paints basically consist of solid particles, called pigments, dispersed in a liquid, known

as the binder, medium, film-former or vehicle. When the paint dries, the binder binds the

pigment particles together in a coherent film that adheres to the surface. The binder

provides most of the properties required to protect the substrate from the environment,

and is the most important constituent of the paint. The binder generally consists of an

organic polymer known as a resin dissolved in a solvent. Paints are generally

categorized according to the binder type, with names such as alkyd, epoxy,

polyurethane, etc. The pigment provides corrosion protection properties along with color

to the film (binder). In addition to binder and pigment, most paints contain additional

solvent (thinner) to thin the paint out so it can be more easily applied. Solvents

completely evaporate and play no part in the dry film. Other additives include extenders,

which are similar to pigments and added as a pigment to build up solid constituent or to

modify paint properties. Other additives include driers, anti-skinning agents and

thixotropic agents which reduce sagging of the paint when applied to a vertical surface.

Paints protect basically by providing a barrier between the substrate and the

environment. They are electrically insulating which impedes the movement of the ions

which take part in the corrosion reactions. Water and oxygen can both diffuse into paint

coatings, although some are more impermeable than others and therefore provide greater

protection.

An inert or barrier pigment such as iron oxide assists in this barrier effect. Leafing

pigments, such as micaceous iron oxide (MIO) and leafing aluminum, provide an

overlapping, shingle effect, providing a further barrier to the corrosive elements and

strengthening the coating. Such pigments also protect the binder from UV

degradation. Aluminum is also used for high temperature paints, but should not be

used where chemical resistance is required. Such pigments are best used in top coats

but can be added to primers. Lamellar pigments will affect the color and appearance

of the film. In addition to the barrier effect, primers usually contain pigments which

can provide additional protection. Inhibitive primers contain chemical compounds

which dissolve in water to some degree and form a protective passive chemical

compound at the anodic sites on the metal. This reduces or prevents corrosion, but

such pigments are only used in primers for atmospheric conditions, not for immersed

environments where they can give rise to osmotic blistering. Red lead and zinc

chromate both provide an inhibitive effect, although primers containing such

compounds are no longer used due to their toxicity. These pigments have now been

replaced by zinc phosphate, although this pigment probably provides protection more

by barrier than inhibitive effect. Zinc-rich primers provide a barrier effect but, more

importantly, have sufficient metallic pigment (90 per cent or more in the dry film) for

them to be able to provide cathodic protection. The zinc powder is in sufficient

concentration for there to be a conducting path between the zinc particles and the

steel. Clearly, the surface must be well prepared so there can be electrical contact

between the zinc and the steel. At a scratch in the coating, the zinc corrodes in

preference to the steel. Additionally, zinc corrodes at a significantly lower rate than

steel and the zinc corrosion products which form tend to block up the pores in the

coating providing further barrier protection [3].

3. MAJOR TYPES OF PROTECTIVE COATINGS

There are several types of paint which are commonly used in oil and gas plants.

Applicable paints such as: (1) Acrylic, (2) Epoxy, (3) Vinyls, (4) Alkyds, (5)

Chlorinated rubber, (6) Coal Tar Epoxies, (7) Polyurethane, (8) Silicone resins, (9)

Polyester and vinyl ester, (10) Zinc-rich paints. Only types with more interest to crude

oil storage tank painting will be described in details hereafter. Other paints details cab be

obtained from reference [2-3].

Acrylic: coatings are derived from acrylic and methacrylic acid and, as there are

many possible polymerization reactions which can occur, there are almost unlimited

ranges of materials available varying from hard, brittle materials to soft, flexible

coatings. They are characterized by excellent color retention; ultraviolet stability and

gloss along with resistance to chemicals, moisture and weathering so are widely used

as top coats. They are available as paints which dry by solvent evaporation which are

mainly used for production line applications, such as automobiles, and as water-based

emulsions which are becoming increasingly important for top coats of structures not

located in aggressive environments. Two-pack or catalyzed acrylics are also available

which are harder, tougher and more heat and solvent resistant than the other types and

can be used as top coats in more aggressive environments. Because of their cost and

health and safety advantages, these are commonly specified where polyurethanes may

have been used in the past. They are generally not used for immersion service or in

strong chemical environments.

Epoxy: systems are generally two-pack convertible products which cure by chemical

reaction forming a film which is strongly adherent, hard and chemical and solvent

resistant. Epoxies are commonly specified where long term protection and

performance is required and where high standards of surface preparation can be

achieved. While alkyds are the workhorse coating under mild to moderate conditions,

epoxies are the workhorse under more severe conditions. In common with other twopack coatings, they require proper mixing before application, there is a limited time

during which the paint can be applied and curing time is strongly temperature

dependent. Many epoxies will not cure below 5 deg C, although epoxies which cure

below this temperature are now available. There are two main types of curing agents

used with epoxies. Polyamide-cured epoxies have better weathering, are more

flexible, cheaper, mixing ratios, are less critical and have the longer pot life, although

this means a longer curing time. Polyamide epoxies are more forgiving of

condensation or high relative humidity during curing. Polyamine-cured epoxies have

better chemical and solvent resistance and are generally used for specialist purposes

such as tank linings. Most are now amine-adduct curing types which means the amine

is partially reacted with the epoxy resin giving a material which is easier to mix and

apply than the straight amine cured epoxies. Epoxies are prone to loss of gloss on

exposure (chalking) although their other properties are unaffected. Often a

polyurethane or acrylic finish coat is specified for epoxies to avoid this problem.

Epoxies can be used as primers, where they can be pigmented with zinc dust, zinc

phosphate or MIO. As intermediate or finishing coats they can be pigmented with a

full range of colored pigments or MIO. They are widely used for offshore structures

and for other aggressive and chemically polluted areas. Maintenance with these

coatings is often difficult since they are hard and tend to harden further on ageing. A

light blast clean is generally required to roughen an old epoxy coating to allow the

new coating to adhere. There have been a number of developments in coatings based

on epoxy resins. Solventless, Ultra High Build (UHB) or high solids epoxies are

available which allow high film builds of a millimeter or more in thickness to be

applied. High build epoxies, as distinct from high solids epoxies, contain inert

pigments which provide an inert, impervious coating which is often used for tank

linings. Epoxy mastics have been developed which are tolerant to hand prepared rusty

steel surfaces. Specially formulated polyamide-cured epoxies have the ability to

displace water from the substrate and such materials can even be applied and cured

underwater. Epoxies can be modified with other resins such as silicones, phenolics or

urethanes to produce improved water, chemical and solvent resistance. Water-based

epoxies are now available which provide the environmental and health and safety

advantages of water-based coatings, although generally do not provide as good

corrosion resistance as solvent-borne epoxies. Epoxy esters are not true epoxies, but

rather single-pack alkyds modified with epoxy.

Coal Tar Epoxies: are epoxies which have been modified with coal tar providing

the advantages of epoxies with improved water resistance. They are less resistant to

solvents than conventional epoxies and only available in dark colors. Because they

degrade from UV radiation, they are not normally used in atmospheric exposures.

They are widely used in sewage industry as they are resistant to hydrogen sulphide

and bacteria attack. They are compatible with cathodic protection and extensively

used for tanks, ships’ hulls and on offshore structures. However, due to the

carcinogenic nature and health issues of the coal tar, they are being phased out and

will be replaced by other coatings, generally conventional epoxies [4-6].

Polyurethane: coatings are based on the reaction between isocyanates and hydroxylcontaining compounds, usually an acrylic, epoxy, alkyd, polyester or similar

material. For protective coatings they are usually two-pack types and the isocyanates

are classified as either aromatic or aliphatic. Both types form a hard, tough film

which shows excellent chemical and solvent resistance, color and gloss retention and

will cure at lower temperatures than epoxies. However, they are more expensive than

epoxies, and more difficult to handle and apply as the resin is moisture-sensitive in the

liquid state and is toxic. Aromatic urethanes, such as toluene di-isocyanate (TDI) are

cheaper and suitable for immersion service. Aliphatic urethanes, hexamethylene diisocyanate (HMDI) for example, have better color and gloss retention. Unlike most

coatings which chalk and yellow after prolonged exposure, aliphatic urethanes

continue to maintain a glossy, `wet look’ years after application.

Because of their hardness, maintenance is difficult as a new coat will not adhere.

However, recoatable polyurethanes modified with acrylic resins have been developed

which are easier to recoat. Moisture-curing urethanes are one-pack materials that

react with atmospheric moisture to cure. These are rapid cure coatings which can be

applied at low temperatures and under adverse weather conditions. However,

moisture must be completely excluded from the raw material and its rapid cure

means overcoating must be carried out quickly or problems with intercoat adhesion

will arise. Elastomeric urethanes are flexible, rubbery coatings which have excellent

adhesion and abrasion resistance, along with resistance to chemicals and weathering.

They are expensive but ideal in abrasive and corrosive conditions. So-called

`isocyanates-free polyurethanes’ are not polyurethanes but catalyzed acrylics.

Polyester and vinyl ester: resins are best known in the reinforced plastics industry

where they are used as binders for glass fibers or other materials to form a range of

products. In the protective coatings area, they are used to form a thick, hard, acid

resistant coating which is often used for tank linings. They are fast curing, but this

makes them difficult to apply. They shrink on curing so are often reinforced with glass

fibers or flakes. They are brittle and should not be used under alkaline conditions since

both the resin and glass break down in such environments. Vinyl esters tend to give

better alkali resistance and adhesion than the polyesters. Both types are often used as

linings for tanks and chemical process equipment.

Zinc-rich paints: have a variety of binder types, but because of their importance in

corrosion protection, are worth considering as a generic group. They all have a high

proportion of metallic zinc powder in the dry film which provides protection by cathodic

protection and barrier action as described above. In addition, zinc corrosion products

(carbonates, hydroxides, etc) fill and seal pores in the coating. Zinc rich paints can have

organic or inorganic binders, although there are a number of categories within each

group. Zinc rich coatings should not be used in aggressive acid or alkali environments

(pH outside the range 6 to 10.5).

Organic zinc-rich: coatings can be divided into single pack and two pack types and can

use virtually any binder that can resist the alkaline zinc corrosion products. The single

pack types have binders made from resins such as chlorinated rubbers, acrylics and

vinyls and are easier to use, but have limited application in the protective coatings field

as the protection provided by them is limited. Use is usually restricted to repairing

damaged and welded areas on galvanized steelwork. Two-pack types are usually based

on epoxy resins, although polyurethanes can be used. These are more resistant and

widely used as primers under atmospheric conditions. Organic zinc-rich paints are

generally easier to use than the inorganic variety, and are somewhat more tolerant of

poor surface preparation. However, they do not provide the protection and durability

afforded by the inorganic type.

Inorganic zinc rich: coatings comprise zinc metal in a silicate binder. As an inorganic

material, such binders have vastly superior weather, abrasion, heat and solvent resistance

over even the best organic binder. In addition, the cement-like nature of the coating

means they have a much greater coefficient of friction than other paints and can be used

on surfaces connected by high-friction grip bolts. Such coatings are generally quick

drying and also provide excellent resistance to humid and marine atmospheres. There are

some problems associated with their use. They are not resistant to acids and alkalis, and

require excellent surface preparation. They must be sprayed and must not be applied too

thickly or mud cracking will occur. They will provide excellent protection on their own,

but can be top coated for additional protection or aesthetic reasons. When overcoating

inorganic zincs, the top coat must be compatible with the zinc and the surface must be

thoroughly cured and clean, or adhesion problems may result. Because of its porous

nature, it is usually advisable to apply a thin, sealer coat before application of the top

coat.

4. CRUDE OIL TANK COATING SELECTION (CASE STUDY)

Based on the previous comprehensive theoretical background on the coating materials,

their applications and selection, a case study is considered in this work inorder to provide

complete details for a tank coating issues. The protective coating system required is for a

20m diameter by 10m height floating roof steel tank for crude oil storage. The location

considered is in an oil terminal at the coast side of Libya. The crude oil is API 35 and the

maximum operating temperature is expected to be 60 Co (140 o F) and the design water level in the tank is 1 meter height. The tank is sand blasted to SA 2 ½ (ISO 8501-1:1988).

For crude oil floating roof storage tanks, surfaces to be coated is categorized as internal

and external. Internal include the tank internal bottom and 1 to 2 m height from the tank

shell. And external surface include the external tank shell and the 1 to 1.5 m area of the

permanently exposed internal surface of the tank shell measured from the top of the tank.

Tank external bottom is not painted due to cathodic protection requirements. This

problem is talked by two approaches; the first is by referring to the recommendation of

four coating suppliers who are approved by local oil and gas companies, and the second

is by referring to the current local companies coating specification and adopted

procedures. An interviews and/or official contacts were made whenever necessary

particularly on the local companies’ side. Coating suppliers were referred to from their

available in hand catalogues (some might need updating), or from their internet web sites.

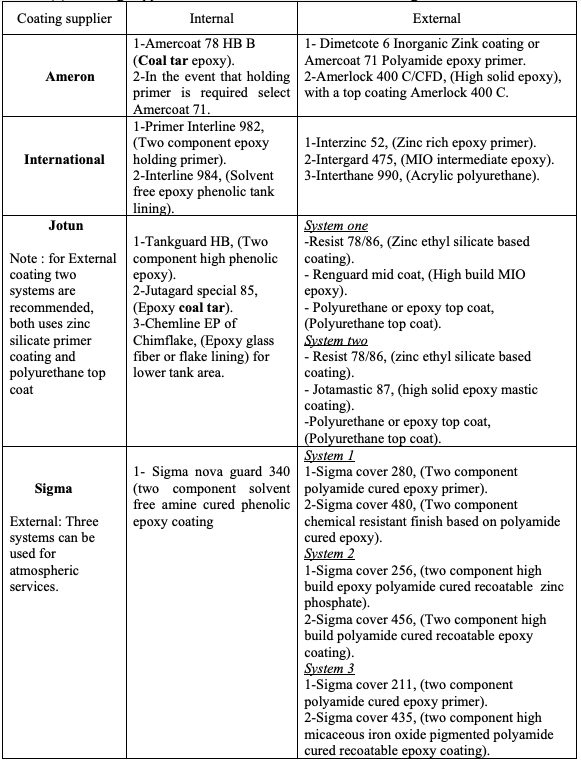

4.1. Coating Supplier Recommendation for Tank Coating

The considered companies deal directly with the oil and gas industry and have developed

coatings especially for this field. We will be presenting the products that they distribute

to North Africa generally and to Libya especially. Four well known and approved coating

suppliers are considered in this study, they are [7-10]:

1) Ameron 2) International 3) Jotun 4) Sigma

There are other high quality coating suppliers, but in general these are the most popular in

Libya. Table (1) shows these suppliers recommendation. As shown, for the external

coating, except Sigma, the most common coating types are:

1- Primer: Zink silicate epoxy

2- Intermediate coat: Epoxy (MIO or high solid)

3- Top coat: Polyurethane

However, according to Table (1) for the internal coating, there is a significant conflict

among the four suppliers. Both Ameron and Jotun still recommend the coal tar epoxy

while International and Sigma do not recommend this type of coating. International

supplier has been contacted and confirms that they do not producing this coating anymore

due to health issue [8]. The available data from Ameron and Jotun might be out of date

and a confirmation needs to be made to investigate their position from this issue. Another

point of difference is that Ameron and Jotun specifically recommends the fiberglass mat

or flakes composite layer for the tank bottom and 1 meter height of the tank shell.

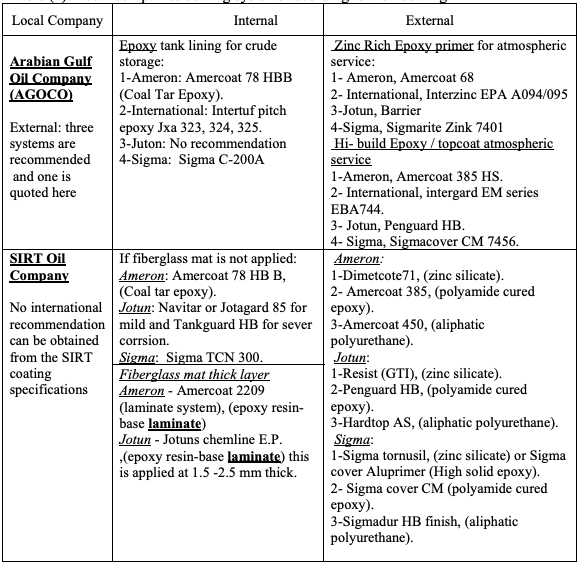

Table (1): Coating suppliers’ recommendation for crude oil storage tank.

4.2. Coating Selection Based on Coating Specifications of Local Companies

There are several Libyan companies that extract, store and refine oil, the following

companies are from the biggest and the most important:

1- The Arabian Gulf Oil Company (AGOCO).

2- SIRT Oil Company.

The general coating specification form these two companies were reviewed and their

recommendations for crude oil storage tank are outlined in Table (2) [11-12].

Table (2): Local companies coating systems according to their coating

Regarding local companies, as can be seen, for the internal coating both AGOCO and

SIRT still recommend epoxy coal tar coating which need to be reviewed. Also, AGOCO

dose not uses the laminated fiberglass internal bottom lining anymore. This issue have

been discussed with the company engineers and explained that their suppressing of the

composite laminate usage was due to both cost and maintenance reasons. They confirmed

that the internal fiberglass composite laminate, if made properly, would prevent corrosion

from the internal side for a longer period, but in case of tank leak it will make inspection

of the bottom plates very difficult if not impossible. This will also make patch repair not

feasible unless the fiber mat is removed which is a difficult and costly task. In such

situations usually a decision to remove the whole bottom would be made. The other point

is that according to company experience most of the problems of the tank bottom came

from the external side of the tank due to soil problems. However, SIRT Oil Company still

using this type of lining and they have confirmed that they have no problems with using

this type of coating. The conflict between the two local companies’ choices might be

attributed to the soil condition being at SIRT performing better than that at AGOCO

locations. In this case we can conclude that unless the soil condition is corrosive the fiber

glass mat may be better except for inspection requirements. This issue seems will be

under debate for a while and need further analysis.

For the external side paint there are not much differences and the choice is similar for

both companies. However, it is to be remarked that Sigma recommendation by SIRT Oil

Company are different from all the three systems recently recommended by the supplier

(See Table 1) which might be attributed to Sigma supplier product developments, and

more specifically their use of two component paints which is reported to have a cost

advantages.

Also, as shown in Table 2, the local companies specify, in their coating specification, the

trade name of the coatings. By comparing these with the coating suppliers names, some

of them were found different, and upon contacting one of these suppliers, they replied

that some coating are either renamed or not produced any more and this is a routine

procedure quite often every now and then. However, local companies’ coatings and

construction specification, once approved, are normally used by the engineering or

projects department. These specifications are anticipated to be subjected to a routine

review at specified interval, usually not less than three years. However, corrosion section

who usually approve the coating specification is generally under the maintenance

department (such as at AGOCO). Therefore, any significant development is expected to

be known by the corrosion section and reported to the engineering department, but it

might not be clearly added to the company general specifications. This might led to what

is happening currently of still existence of the « Coal Tar Epoxy » coating, which is

reported to have some health hazards.

4.3. Tank Bottom External Side

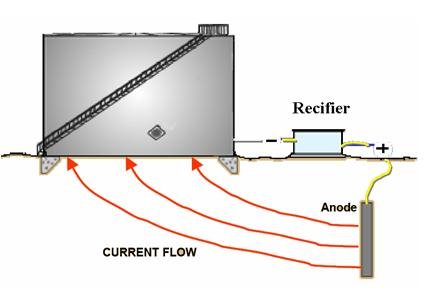

A standard practice in most of the Libyan oil and gas companies is not to coat this side

due to cathodic protection requirements, which is agreed. However, less concentration

seems to be given to the backfill material underneath the tank bottom. Some construction

specification calls for asphalt pad surfacing material to be put at the top of the backfill

material. The surfacing material is 80 mm layer of hot-mix-cold laid bituminous asphalt

cover over a prime coat. This layer should not be done if cathodic protection would be

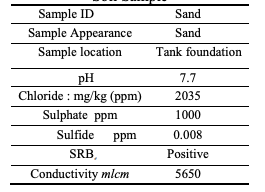

installed as it would work as insulation for the CP protection current (see Figure 3).

Furthermore, most specifications ask for compacted salt free sand which is again will do

very well. However, two issues can be emphasized here, the first is that some locations as the one under consideration, may have bacteria (see Table 3), which mean that the tank area soil need to be replaced totally. The second issue is that both salt and bacteria testing

of the backfill material need to be clearly stated in the tank construction specifications.

As if not clearly stated contractors will not be obliged to do them.

5. CONCLUSIONS

Therefore, from this work, the general coating characteristics are described and the

particular tank coating selection requirements is highlighted. A case study to apply the

previous coating selection theory has been undertaken and two coating selection

approaches were followed; the first is by referring to four well known coating suppliers

and the second by referring to two local oil and gas companies specifications. This

allowed most of the related information gathered for further analysis and discussions.

Some of these efforts finding are:

1- Regarding the internal side, coal tar epoxy application is suppressed internationally

and need to be reviewed by local companies due to health hazards.

2- The tank water and basic sediment area is covered by either paint coating supported by

CP system or thick fiberglass laminate. A conflict of requirements currently exists

between coating suppliers together and also between local companies. This issue needs

further research and investigation even though the authors are convinced by the use of the

coating with CP option.

3- Regarding the external side, the Zink silicate epoxy primer, and the polyurethane top

coat showed more dominant usage. The intermediate coat is mostly epoxy either as a

single or two component coating.

4- According to AGOCO maintenance records it seems that most of the tank problems

are from the foundation side and, more focus should be given to it. Various conflicting

requirements for the backfill material do exist and need to be investigated and clarified.

Also, some of the specification of the tank soil call for mixing the backfill sand with

bitumen layer which proven to have diverse effect on the tank cathodic protection. The

type of soil requirements is said to be salt free soil. However, full chemical analysis

seems necessary as sulfide reducing bacteria (SRB) and other corrosive materials are

some times available and in such circumstances a totally new and clean backfill material

need to be used.

| – Conference: The 6th Libyan Corrosion Conference, Tripoli, Libya, – November2007, Pp 460-472. – Authors: Mohamed Abdelgawad Gebril , Farag Shuaeib – Source: researchgate.net – Recent Advances in Protective Coating of Crude Oil Storage Tanks |